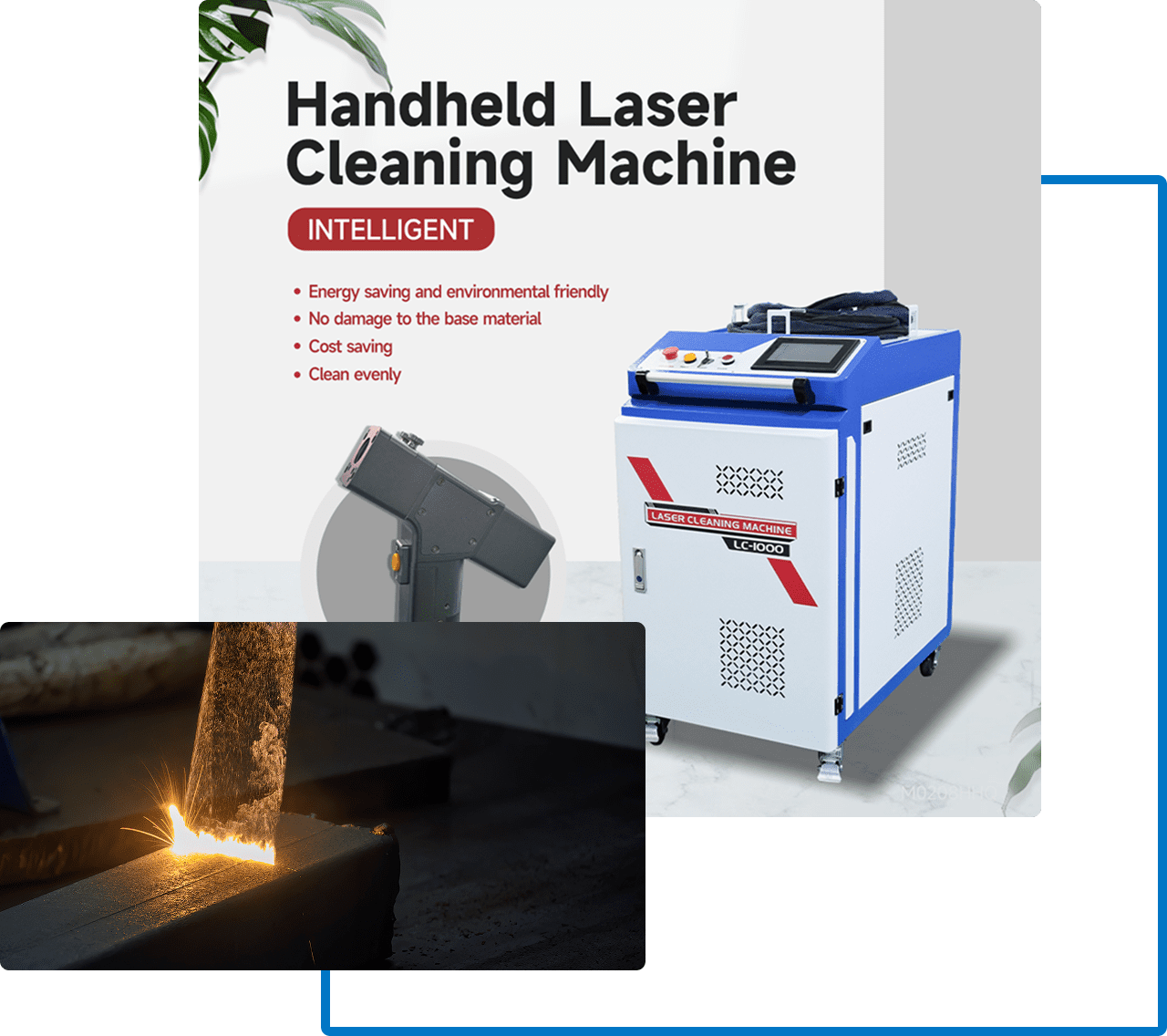

Eco-Friendly Laser Cleaning Solution

Rush Powder Coatings Inc.’s advanced laser cleaning machine provides damage-free cleaning for oxidized, painted, and oily surfaces. In just seconds, surfaces are renewed with precision and efficiency. Unlike sandblasting, laser cleaning generates little to no waste and requires no additional cleanup. The laser safely absorbs and removes contaminants without affecting the underlying material, making it a safer and more sustainable cleaning method.

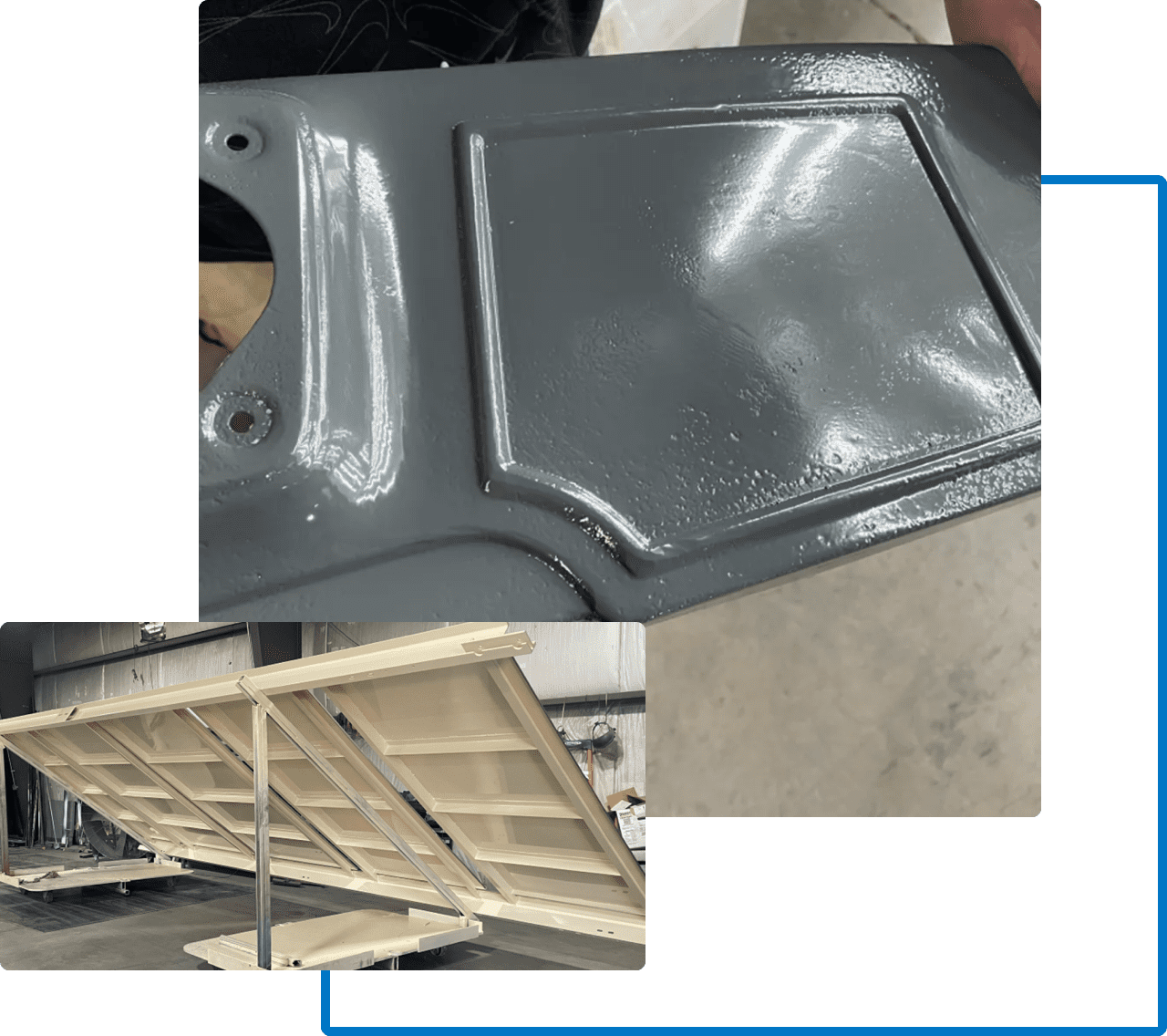

Ideal for Delicate Surfaces

Laser cleaning is the perfect solution for materials that must remain unaltered. We have successfully cleaned aluminum surfaces, threads, and thin gauge metals—materials that would be damaged by the abrasiveness of sandblasting.

Restoring Historic Components

For a 1932 dash panel, RPC removed layers of paint, body filler, and oxidation accumulated over decades. This process restored and protected the panel, ensuring its usability for another 70 years.